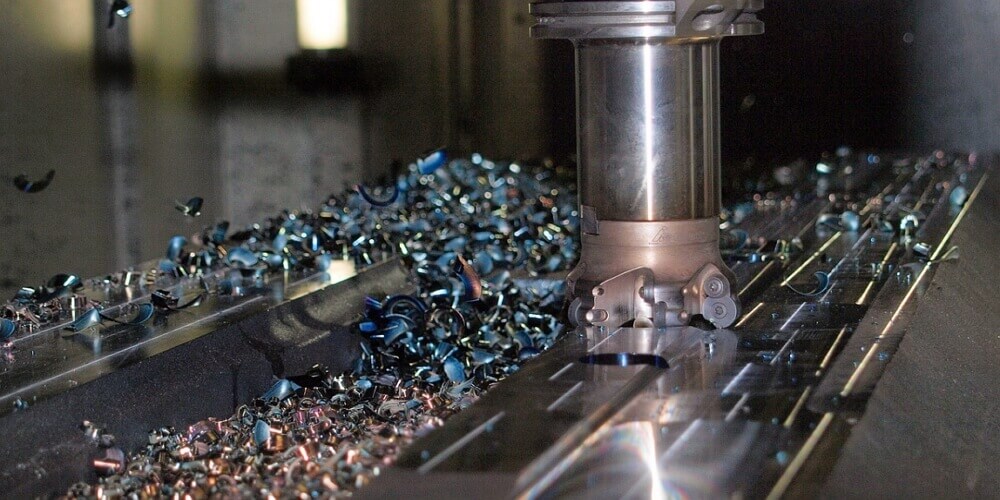

High precision tools are the metal cutting tools used by manufacturers for precision machining of different components and materials. This usually for the purpose of making descriptive measurements.

High precision tools market has many tools on its list. Some of these tools are grinders, drilling machines, boring machines, lathes, milling machines and gear cutters all with high precision.

These tools are designed to be precise and accurate during machining processes. The high precision tools aim to increase accuracy.

Application of High Precision Tools

High precision tools have gained ground in the market because of its versatile application in various industries in the world.

Some of these industries include:

- The engineering industry

- The healthcare and medical industry

- The oil and gas industry

- Defense industry

- Aerospace industry

With the help of high precision tools, these industries have been able to improve their ability to manufacture needed high precision components for machines.

Working with a wide range of materials, most high precision tools are designed using Computer Numerical Control (CNC).

CNC is the automation of mechanical systems with functions that have been defined in advance. In CNC the motions have been programmed and a software does the operations.

The Dynamics of High Precision Tools Market

While high precision tools are applicable to a lot of industries, some industries need it more than others. Some of these places that have various areas for which high precision tools are needed are:

- The metalworking industry

- Plastics fabrication

- Machining of automotive parts

- Machining of aerospace parts

- The medical industry. Etc.

With the slow but steady climb of industrialization in countries around the world, the demand for high precision tools is expected to significantly rise in coming years.

High precision tools market is a bit shaky at the moment. This is because manufacturers are taking the hit and incurring extra cost of training labor force and recruiting consultants and specialists.

The fluctuating prices of raw materials is major contributor to this market disturbance. Manufacturers now have a threat to the pricing structure of these high precision tools.

All of these factors have led to higher cost of production and thus, making its mark on the market growth of high precision tools.

How Are High Precision Tools Divided in The Market?

Like every other product in the market, high precision tools are divided into approachable groups for each target market.

High precision tools are segmented. The segmentation is based in the machine type, the sales channel. It is also segmented by technology and by application.

Based On Machine Type

- Milling machines

- Boring machines

- Grinding machines

- Gear cutters

- Lathe machines

- Drilling machine

Based On Application

- Aerospace

- Metal foundry

- Power energy

- Woodworking

- Automotive

- Shipbuilding

Based On Sales Channel Type

- Offline

- Online

Base On Technology Type

- Computerized Numerical Control (CNC)

- Convectional

Conclusion

Based on personal analysis, high precision tools remain a very versatile tool across many industries. And there is no doubt of how much progress will take place in a few years.